REVO M1A

Professional Desktop CNC Mill

Your new workfellow!

In Factory In Workshop In Office

Production is everywhere with M1A

You can manufacture in your workshop, office and even in your garage thanks to M1A’s ability to work with standard city electricity, strong structure and portable, compact design.

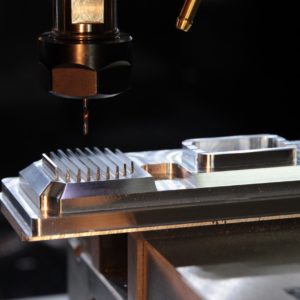

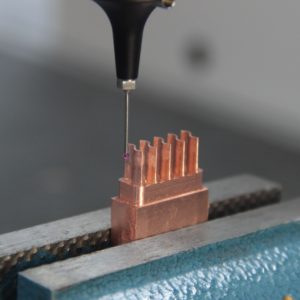

Make some room on your desk if you want to mill materials such as aluminum, copper or plastic at high speed, high quality and efficiency! All processes desired to be made with a CNC mill like milling, drilling and engraving are on your desk now with M1A.

Be Independent in Production!

Work independently by moving your production to your own facility with M1A and control the entire production process from prototype to final product.

►Protect your know-how and design.

►Speed up the development of your designs.

►Improve the quality of your prototypes.

►Lower your costs.

►Free your designs.

►Gain opportunity to test, change and remake faster in your R&D process.

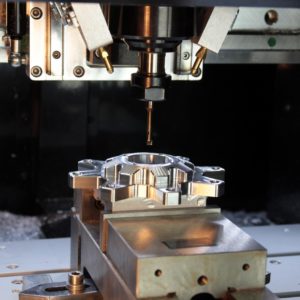

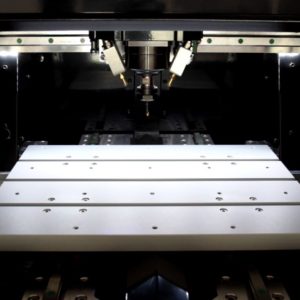

Wide and Functional Working Area

Flexible working opportunity where all workholding techniques can be applied

Its 30 mm thick, T-slotted, thread holed and dense anodized table allows work pieces to be inserted fast and easy. Its fully closed structure and specially designed door mechanism provides full access to working place while keeping your environment clean and silent. It doesn't need additional ambient lighting thanks to its strong interior lighting.

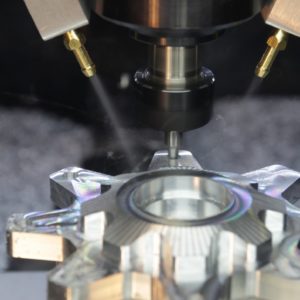

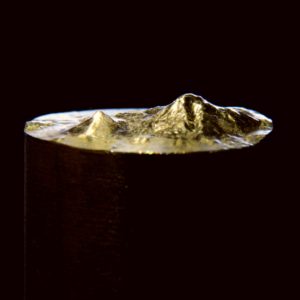

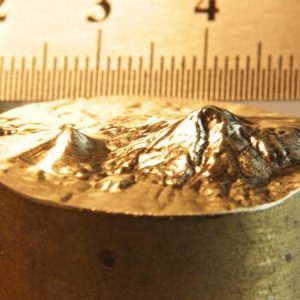

Speed Precision Accuracy

High precision with the ability to 0,01 mm positioning and repeatability

M1A, produced by carefully combining parts all produced with vertical machining centers is designed for fast and accurate production 24/7 with its precise ball screws those are directly driven by closed-loop motors on all axes, linear guide rails and sensors.

M1A's aluminum machine frame absorbs the vibration that occurs during the production and presents outstanding surface quality on work piece.

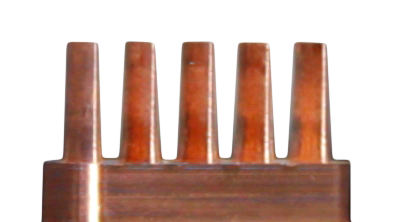

Powerful Spindle Efficient Cooling

M1A presents power, speed and efficiency together in all your delicate works with its ceramic bearing spindle motor which has 1.5kW power and 24000 rpm speed. Efficient mist cooling system removes chips and keeps the workpiece and cutting tool clean while cooling it.

Professional Controller

Industrial hardware, user-friendly interface

M1A does not need a computer connection with its industrial controller and is ready to use in 10 seconds. M1A is not affected by problems caused by freezing, virus or power outage in personal computer systems, and offers continuous and stable operation.

With 15 ”LED operating display, real-time and user-friendly interface, CNC usage is easier than ever!

Work in Safety in Any Environment

What happens inside, stays inside

M1A keeps you safe at all times with its fully closed cabinet, unbreakable polycarbonate window and safety switch that puts the operation on hold when the door is opened, while helping to prevent overlapping accidents that may occur in the spindle and table with its sensors. The automatic door interlock, which can be added upon request and activated during operation, prevents the door from opening completely while the machine is running.

Technıcal Detaıls

- WORKING AREA450x350 mm (X, Y)

- AXES TRAVELS465x365 mm (X, Y)

- Z AXIS TRAVEL170 mm

- FOOTPRINT790x900x950 mm

- WEIGHT160 kg (Approx.)

- SPINDLE1,5 kW / 36000RPM

- TOOL HOLDERER16 OR ISO 20 WITH ATC

- TOOL SIZEUP T0 10 MM

- REPEATABILITY<0.017 mm

- FEEDMax. 6000 mm / min

- CONTROL DISPLAY15" Touch Screen

- POWER230/110 V 1P (2,5 kW MAX)

- MAX WORKPIECE WEIGHT25 kg

- INCLUDED ACCESORIES

- ER16 collet set

- ER16 wrench set

- Mist coolant system

- MPG Handwheel

- Aluminum clamp set (x4)

- T slot nuts

- Power cord

- OPTIONAL ACCESORIES

- 4th axis module

- Mechanical tool setter

- Auto tool setter

- 3D touch probe

- Vacuum chuck

- Vacuum generator set

Frequently Asked Questıons

Nonferrous metals like aluminum, copper, brass, silver; and plastic and composite materials like POM, castermid, plexiglass, polycarbonate, polyethylene, PEEK, carbon fiber, Alucore can be milled with M1A.

Yes, even the hardest aluminum alloys like 7000 and 2000 series can easily be milled with M1A.

Precision is a concept that should be considered regarding to qualification of the work. M1A works with a maximum error of 0,017 mm at 100 mm. If this ratio meets your requirements it means M1A is precise enough to be able to mill aluminum molds.

Yes. M1A is able to mill PCB with its low vibration body and precise equipment. Especially with the use of a vacuum table, the problems that may occur due to the bevel of the card to be milled are eliminated by ensuring the card to stay at the same level with the table. If your environment is not suitable to use vacuum equipment, we recommend you the product Cube 3D of the company Derinmotion, that has been developed for PCB production and has surface leveling system. https://derinmotion.com/urunler/kategori/makineler

M1A is not suitable for pocket milling, sizing, drilling on materials like steel, titanium, inconel but surface milling and engraving operations can be done on these materials. If you need a specific solution for milling steel, please contact us from the contact section below.

Vertical machining centers are machines manufactured to mill extremely hard metals such as stainless steel and titanium, and materials that weight up to hundreds of kilos. They owe these abilities to be having a body that weighs tons, very big linear motion elements and motors. As well as steel materials, vertical machining centers are indispensable when also milling large aluminum blocks, such as landing gear of an airplane or wheel rim of an automobile. But when it comes to milling small materials such as aluminum and plastic in a few cm thick plates form, the majority of vertical machining centers are a bit slow and unnecessarily powerful for this job. Additionally, while aluminum and plastic can be milled with very high RPM at very high speeds, a vertical machining center that is produced to mill steel and has 8000-10000 RPM works quite inefficiently. Besides, vertical machining centers take up a lot of space, are very heavy and use a lot of energy. It is not possible to use these machines in office, garage or a small workshop and their maintenance and operating costs are also very high. But M1A has lots of advantages like its spindle motor working at 24000 revolutions, being light and portable, taking up little space, having low maintenance and operating costs and not requiring an operator. If you mostly work on aluminum and plastics and the parts you mill are not bigger than 350*450 mm and not heavier than 25 kg in total, it means there is no serious reason for you to buy a vertical machining center.

3D printers have a more practical use according to CNC milling machines. But when it comes to working with real materials, a 3D printer is often not a substitute for a CNC milling machine. While it is possible to work with almost all materials with CNC mills, 3D printers often present you a product that can only be a model. And 3D printers that can print at higher quality with different materials are worth hundreds of thousands of dollars. If the prototype you want to obtain will be only a visual model of the final product, a 3D printer will probably meet your needs. But if you want to work on aluminum, brass, copper, wood and various plastics, to obtain smooth and if necessary transparent, end-product looking and durable prototypes, M1A will be the right solution for you. Beyond prototyping, you can also manufacture your final product with M1A.

The body of M1A is created by precision processing and carefully assembling of aluminum cast plates. There are precise linear rails and ballscrews in all axes of the M1A.

Closed loop motors are used in the drive system of M1A. Thus, motor drivers consistently check whether the given command has been fulfilled or not and prevent losing step. Besides, elements that may cause movement gaps such as belt pulley or reducer are not used in M1A. The axis motors of M1A are directly connected to ball shafts with precise couplings.

Yes. If your work is interrupted for any reason, M1A remembers where you left when restarted and ensures you to resume from that point. You can also pause your long duration works completely on your own wish, then resume from where you left.

Yes, M1A is CE certified.

M1A is produced with two spindle options. In the standard version with manual tool change, the spindle motor is compatible with ER 20 collet and tools with a diameter up to 13 mm can be used. In the other version with automatic tool change ISO 20 holder with ER16 collet exists and tools with a diameter up to 10 mm can be used.

No. M1A has its own control unit and control panel. Thus, it does not need an external control computer and it is enough to plug it in to operate.

M1A is compatible with all popular CAD/CAM softwares like Fusion360, SolidCAM, Mastercam, PowerMill, Aspire, Artcam.

Yes. Upon your request, a 4th axis module with a lathe chuck of 80 or 100 mm diameter can be added. Even if you buy our machine with 3 axes, you can add a 4th axis at any time you want afterwards.

Yes. M1A is produced in such a way that it can pass through all standard 80 cm wide doors and can work with 230/110 V city electricity. The fully enclosed cabinet keeps the sound level below a conventional vacuum cleaner even at full load, while providing you a chip-free and safe working environment.

To start working with M1A, it is enough to plug the power cord in and turn on the main switch. M1A will be ready to use in 10 seconds and no additional equipment is required for operation. If you want to use features such as automatic tool changer, dust extraction, vacuum table, spray cooling, you will of course need to use a vacuum pump, dust extraction system or compressor for these equipment to work.

Yes. M1A has a mist cooling system that cools both the cutting tool and the workpiece by mixing a small amount of cooling liquid with compressed air. In this system, alcohol based chemicals are used as cooling liquid. This system provides a cleaner working environment compared to systems using boron oil or cooling water; lowers maintenance and usage expenses; protects environment; and does not leave oil, dirt and stain on the material you mill. 6-8 bar clean and dry air intake is required for the cooling system to work.

M1A is suitable for both working with CAM software and for traditional manual programming. Of course, CAM software often offers a faster and safer working possibility compared to traditional programming.

M1A is suitable to work 24/7 as long as maintenance and usage instructions are followed.

Yes. M1A is a desktop machine as standard but besides that it can also be delivered with a carrier stand with a 100 liter chip bin. If your operation volume is high and therefore chip cleaning will cause you lose time, the stand with 100 liter chip volume will be more suitable for you.

With the assembly, calibration and test phases, the delivery time can take 2 to 3 months depending on the intensity of current M1A demand. The product is sent to your address in a palletised wooden box after all the tests are completed. With its plug and operate feature, M1A can be put into service like a refrigerator without needing any technical knowledge. It does not require any specific knowledge or service for installation.

M1A control panel has a very easy usage and a simple interface compared to conventional VMC panels. Documents and videos required for the training of the controller are sent with the machine.